Keeping your trucks running smoothly is quite simple. It all comes down to scheduled system checks, identifying problems before they escalate, assessing fleet condition, and implementing proactive strategies. Routine inspections and repairs guarantee minimal downtime, enhanced performance, and security. Expert guidance from professionals like Jim will guide you through fleet maintenance through the effective use of technology, thorough documentation, and qualified staff. Dive into this complete guide to fleet maintenance and discover cost-effective operations. There's much to explore and master!

Key Takeaways

Recognizing the Critical Role of Routine Commercial Vehicle Upkeep

While it may appear challenging, mastering regular truck and fleet maintenance is crucial for any successful business. The benefits of maintenance greatly surpass the time and effort invested. Routine inspections and maintenance can substantially prolong the lifespan of your vehicles, preventing expensive replacements. Furthermore, there's a clear link between regularly maintained fleet and enhanced fuel performance. This translates to decreased fuel spending, enhancing your total operational efficiency. Additionally, routine servicing can uncover minor concerns before they develop into major issues, saving you expensive repair costs in the future. Therefore, never discount the value of regular upkeep; it can be a true difference-maker for your operation's success.

Understanding Fundamental Parts of a High-Performance Maintenance Framework

To ensure your fleet's efficiency and durability, it's critical to pinpoint the key components of a well-designed maintenance program. You'll have to grasp the basic principles of maintenance, assess the health of your fleet consistently, and put in place preventive measures in advance. With these established, you're well on your way to minimizing downtime and optimizing productivity.

Fundamental Maintenance System Elements

If you aim to improve your fleet's efficiency and lifespan, implementing a robust maintenance program is essential. Critical elements of the program encompass periodic inspections, regular servicing, and anticipatory repairs. Each of these elements is instrumental in avoiding major malfunctions and decreasing downtime. While the benefits of a maintenance program are significant, don't ignore the setup hurdles. These can range from logistical issues and staff resistance. Yet, with strategic organization, transparent dialogue, and dedication to training, these barriers can be overcome. Remember that an effective maintenance program goes beyond fixing problems; it stops them from occurring. It's an dedication in your fleet's success – and it's one that delivers substantial benefits.

Fleet Health Monitoring

When examining the key elements of a effective maintenance program, understanding the significance of fleet condition monitoring takes center stage. It extends beyond ensuring vehicle functionality, it focuses on enhancing fleet performance. Fleet monitoring systems provide a comprehensive view of your fleet's status, empowering you to spot potential issues prior to escalation.

These monitoring systems track vital parameters like fuel performance, tire conditions, engine health, and more. By leveraging this data, you're not just guaranteeing the lifespan of your fleet but also saving on unnecessary repair costs. Keep in mind early detection is essential in fleet management. So, implement dependable monitoring technologies and stay ahead of the curve. Don't merely address problems, anticipate them. Monitor your fleet's status regularly and your operation will perform optimally.

Implementing Preventive Measures

Although tracking your fleet's condition is crucial, implementing preventive measures is equally important to maintain a successful maintenance program. You must detect potential concerns before they escalate into expensive repairs and operational delays. So, let's talk preventive measures.

A key measure is establishing a detailed maintenance checklist. This document should outline all essential checks, maintenance procedures, and replacements. Routine engine checks, tire servicing, and oil changes are fundamental. However, remember to check smaller components like wiper blades, lights, and filters.

Your checklist should also include a schedule for all maintenance tasks. Adhering to this timeline guarantees that your fleet stays in top shape. Don't forget, preventive measures cuts down on costs, time, and troubles in the future.

Essential Routine Checks for Truck and Fleet Maintenance

To guarantee your truck and fleet stay in top condition, you need to focus on regular maintenance examinations. These checks encompass scheduled maintenance inspections and key parts inspection. By adhering to these essential routines, you'll extend your fleet's longevity, enhance operational performance, and in the end, minimize expensive fixes.

Routine Equipment Inspections

Routine maintenance inspections are your strongest line of defense against unexpected fleet and vehicle failures. This maintenance gives you an opportunity to identify and resolve problems before they develop into costly repairs or dangerous accidents. One of the primary benefits of routine maintenance is the reduction of operational delays, which can significantly affect your company's productivity and bottom line.

Essential Component Inspections

Building on the significance of scheduled maintenance inspections, let's move towards the specific essential component checks that should be conducted regularly to guarantee maximum truck and fleet performance. Start with the brake system – verify all components are operating correctly, from brake pads to fluid levels, and checking for leaks. If ignored, brakes could fail, leading to catastrophic incidents. Checking tire pressure is equally crucial. Low pressure increases fuel consumption and tire wear, while overinflation may lead to a blowout. Invest in a high-quality pressure gauge for exact readings. Remember tires should be cold during checks for optimal results. Routinely carrying out these important checks can save you from costly repairs and potential accidents. Stay safe on the road.

Essential Fleet Maintenance Practices for Peak Performance

While overseeing a fleet, it's crucial that you emphasize preventative maintenance to guarantee peak efficiency. Setting up a comprehensive preventative scheduling system is key. This prevents unnecessary wear and tear, and lowers the probability of unscheduled downtime. You should schedule regular maintenance and inspections based on mileage, time, engine hours, or fuel used. Keep in mind each vehicle is distinct and could require a customized approach.

Maintenance training is a crucial approach to secure peak efficiency. Provide your staff with the essential skills to detect potential issues early on. This saves both time and effort but also reduces costs. The fusion of scheduled prevention and maintenance education will lead to a more efficient and reliable fleet. Prevention is always better than cure.

Crucial Pointers for Truck and Fleet Restoration and Repair

Even though truck and fleet repair and restoration may seem daunting, understanding the process can make it much simpler. Your initial step is to understand different maintenance methods. This knowledge will help you identify issues effectively and promptly. Next, prioritize restoration projects based on how serious the issues are and the truck's function in your operation. Routinely examine all units for developing concerns and fix them immediately to stop issues from worsening. Don't forget, renovation isn't simply problem-solving, it's focused on enhancing the unit's efficiency and durability. Finally, consistently choose high-quality parts for maintenance; they'll provide better durability and performance. Follow these principles, and you'll navigate truck and fleet repair and restoration successfully.

Leveraging Sector Developments for Enhanced Fleet Management

To stay ahead in the trucking industry, it's crucial to click here utilize industry innovations for enhanced fleet maintenance. Technological advancements are transforming the maintenance landscape. Embrace data analytics to monitor your fleet's operations and anticipate potential issues in advance.

Modern tracking solutions effectively monitor engine conditions and status, fuel consumption, and operator performance. Leverage this crucial data to schedule predictive maintenance, minimizing costly operational interruptions.

Always prioritize software updates. These improvements generally include critical updates and fixes that enhance your fleet's performance and safety. Be aware that fleet management goes beyond physical upkeep. You're operating in a digital period, and adapting to market improvements will safeguard your vehicles' longevity and profitability. By utilizing effective procedures, you will decrease costs and time, and safeguard human life.

FAQ

What Qualifications Are Required for a Professional Commercial Fleet Technician?

You will require an official certification, meeting the standards of a recognized mechanic institution. Furthermore, you must pass a comprehensive skill assessment, demonstrating your competency in different areas of fleet service and repair. Prior experience is essential!

What's the Recommended Tire Replacement Schedule for Fleet Vehicles?

As the seasons change, you should regularly check your fleet's tire tread regularly. Yet, it's generally recommended to swap out tires every 3 to 6 years, according to road conditions and usage patterns.

What Are the Common Signs of Engine Trouble in Trucks?

You'll notice engine issues in trucks through indicators including strange engine sounds or even poor fuel performance. Additional indicators are unusual exhaust smoke, fluid leakage, or possibly a continuously lit check engine warning.

Does Technology Play a Role in Improving Truck and Fleet Maintenance?

Technology plays a vital role in enhancing truck maintenance. Telemetry systems deliver real-time data, while smart systems anticipate issues before they occur. You'll notice less vehicle downtime, improved safety and ultimately, financial benefits. It's transformative.

Do Different Fleet Vehicles Have Unique Maintenance Requirements?

Various vehicles need distinct maintenance schedules. You need to consider the vehicle's purpose, carrying capacity, and operating terrain, as these elements greatly influence needed upkeep. Always adjust maintenance based on the vehicle classification.

Conclusion

In the end, it's all about maintaining optimal fleet performance, isn't it? Regular maintenance isn't just a suggestion, it's essential. By pinpointing crucial elements, conducting routine checks, applying preventive maintenance approaches, and utilizing modern solutions, you're doing more than basic maintenance, you're honing a well-oiled machine. And remember, truck and fleet repair isn't a failure, it's an opportunity for restoration. Maintain your dedication, and you'll experience your fleet's efficiency, reliability, and longevity achieve new levels.

Brian Bonsall Then & Now!

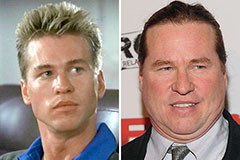

Brian Bonsall Then & Now! Val Kilmer Then & Now!

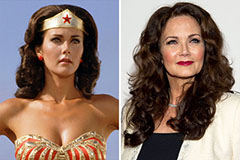

Val Kilmer Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Kane Then & Now!

Kane Then & Now! The Olsen Twins Then & Now!

The Olsen Twins Then & Now!